Overview

The Stanford Microfluidics Foundry is a ~1000 square foot class 10,000 clean room that consists of two main area: an inner room dedicated to photolithographic production of microfluidic molding masters and an outer room dedicated to production and testing of microfluidic devices produced via soft lithography.

Mold Fabrication Equipment

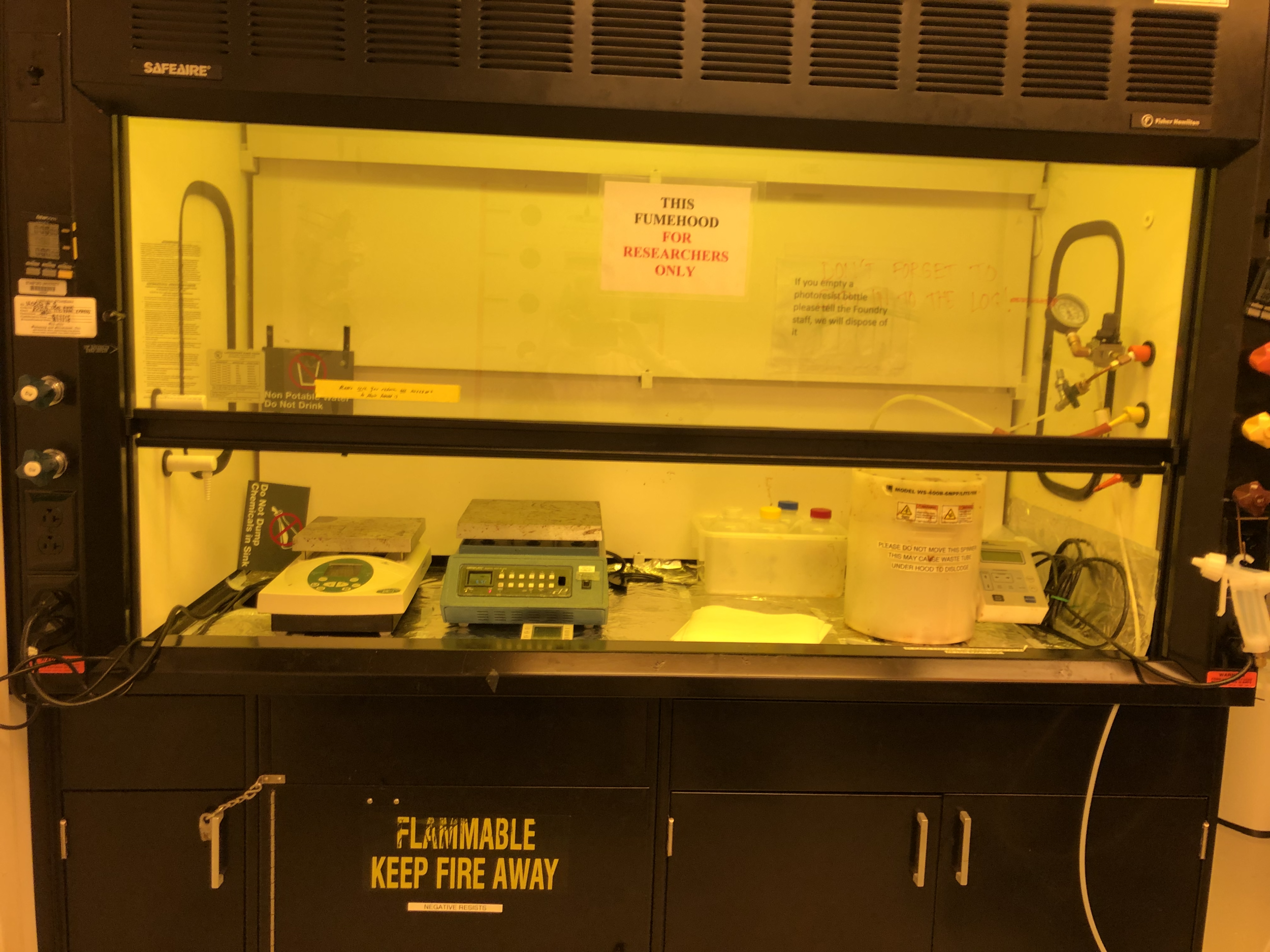

Wet bench processing hood #1

Wet bench processing hood #2

Photoresist spinners

Torrey Pines programmable hot plates

Karl Suss MA6 mask aligner

Photoresist development hood

Wafer inspection stereoscope

Device fabrication equipment

Wafer silanization hood

Convection oven

Profilometer

THINKY centrifugal mixer

Device inspection stereoscope

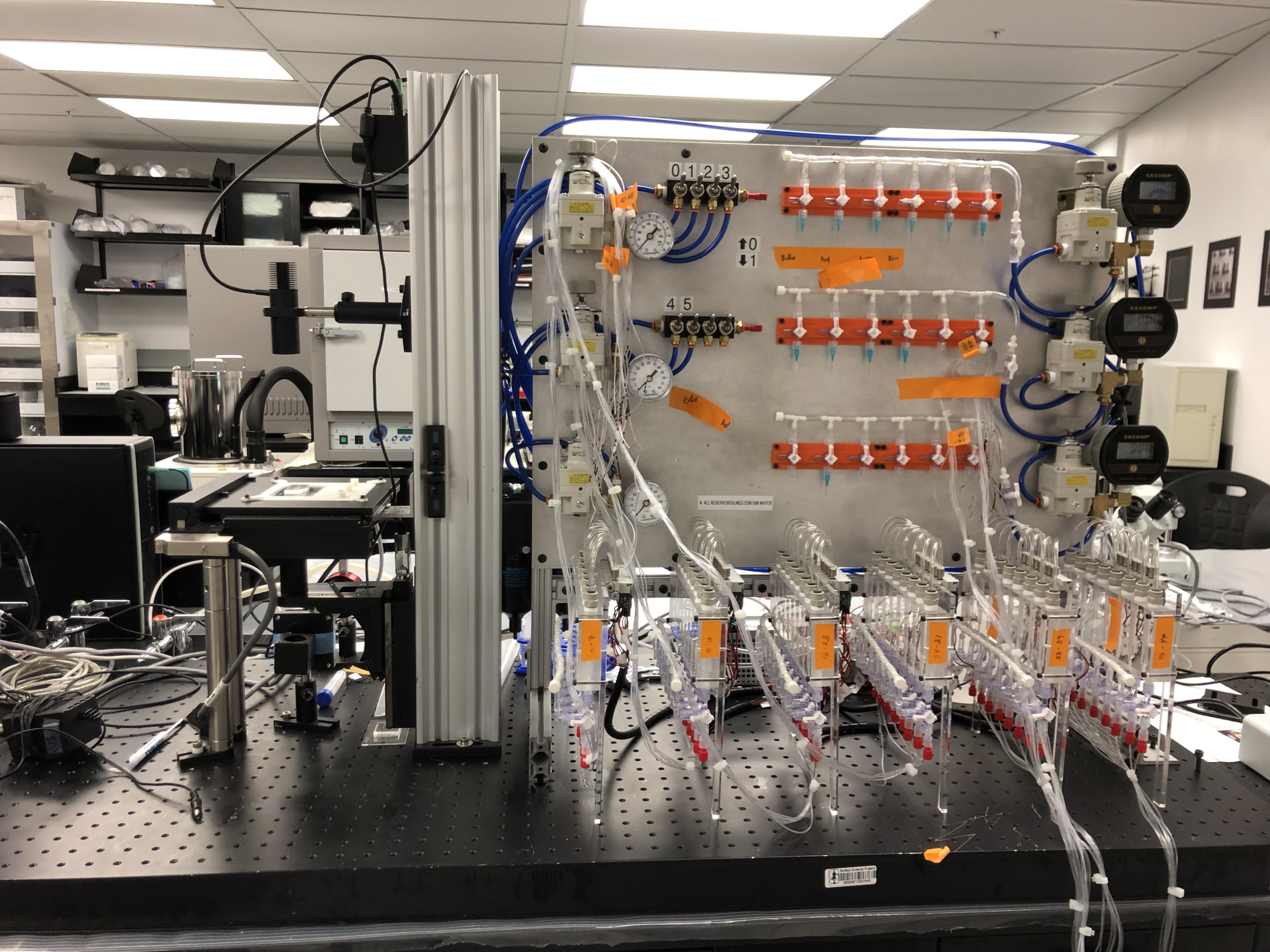

Pneumatic manifold for device testing

PDMS spin coater

Micro drill press for hole punching

PDMS spin coater

Plasma cleaner